Robust and Intuitive Meshing of Bone Implant Compounds

Abstract

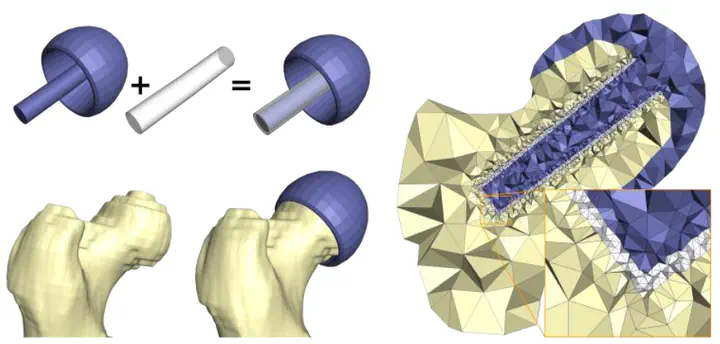

To preoperatively assess the functional outcome of a total joint replacement, finite element analysis can be used for an objective evaluation of individual implant configurations. For large scale studies, where the implant configuration is varied in size, position or design, numerous finite element meshes have to be generated. To improve the planning process we propose a method that outputs a merged tetrahedral mesh of the patient’s jointanatomy and an arbitrarily positioned implant geometry suitable for finite element analysis. Our approach has several advantages: (1) it avoids error-prone intermediate stages, e.g. data type conversion, (2) it is able to preserve constraints such as sharp edges and (3) it can be fully automated by initially defining a few parameters that describe the desired geometric accuracy and element quality. Based on the meshing of 100 different patient-specific bone-implant setups at the tibia (shinbone), we show that our approach produces high-quality meshes in all cases automatically.